Bicycle Design & The Future of Carbon Fiber

For the past 35+ years, MODYN has designed the future of bicycles. We’ve experimented with different bike seats, redesigned and streamlined frames, engineered new components and worked on every detail, from the bike’s geometry to how the grips are integrated into the handlebar. Along the way there have been some big, impactful innovations. But in all of our years working on bicycle design, there have been few opportunities to take this 200-year old transportation method and make something more sustainable, durable and exciting all at once.

In a newfound partnership with Covestro and REIN4CED, our companies are embarking on a

design study to explore the possibilities for a new, totally streamlined carbon composite gravel bike frame. Designed with Covestro’s innovative carbon fiber composite and leveraging REIN4CED’s high-end manufacturing in Belgium, we’re designing a gravel bike that is more durable, eco-friendly, comfortable, streamlined and exciting to ride. Plus, it can be made right here in Europe.

Together, we just submitted the bike for a Red Dot Concept Award. But, while the jury is still out, we thought we would give you a sneak peek at the bike and explain why the carbon composite market is such an exciting opportunity at the moment.

Carbon fiber is sought after for bicycle design and Formula One racing because it’s lighter, stronger, and stiffer than aluminum. However, carbon fiber is quite impact-sensitive. Cyclists benefit from lighter bikes and improved damping and torsional stiffness, but these bikes have limitations. A crash can total the carbon fiber frame.

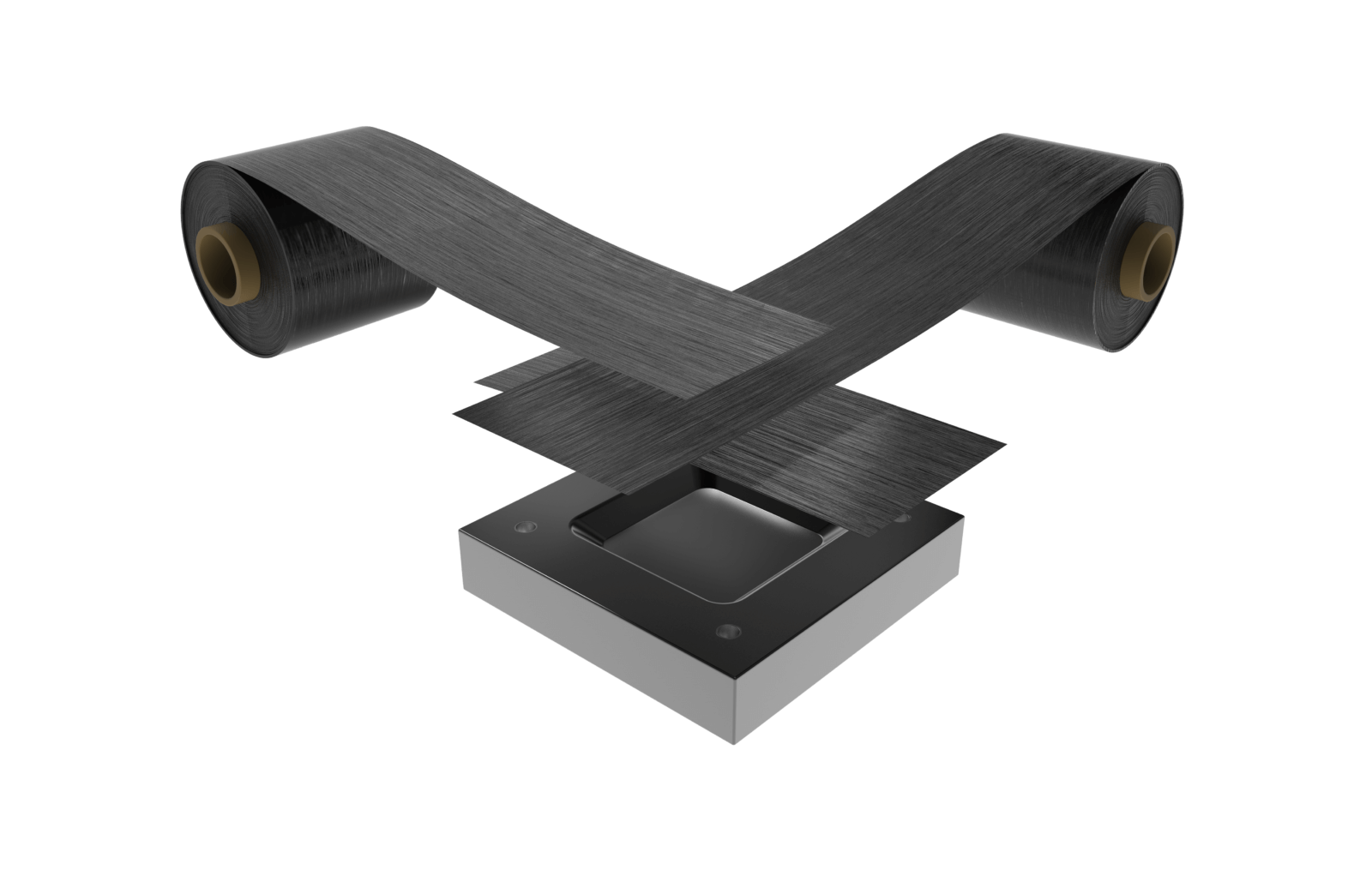

Introducing Maezio® Thermoplastic Carbon Fiber

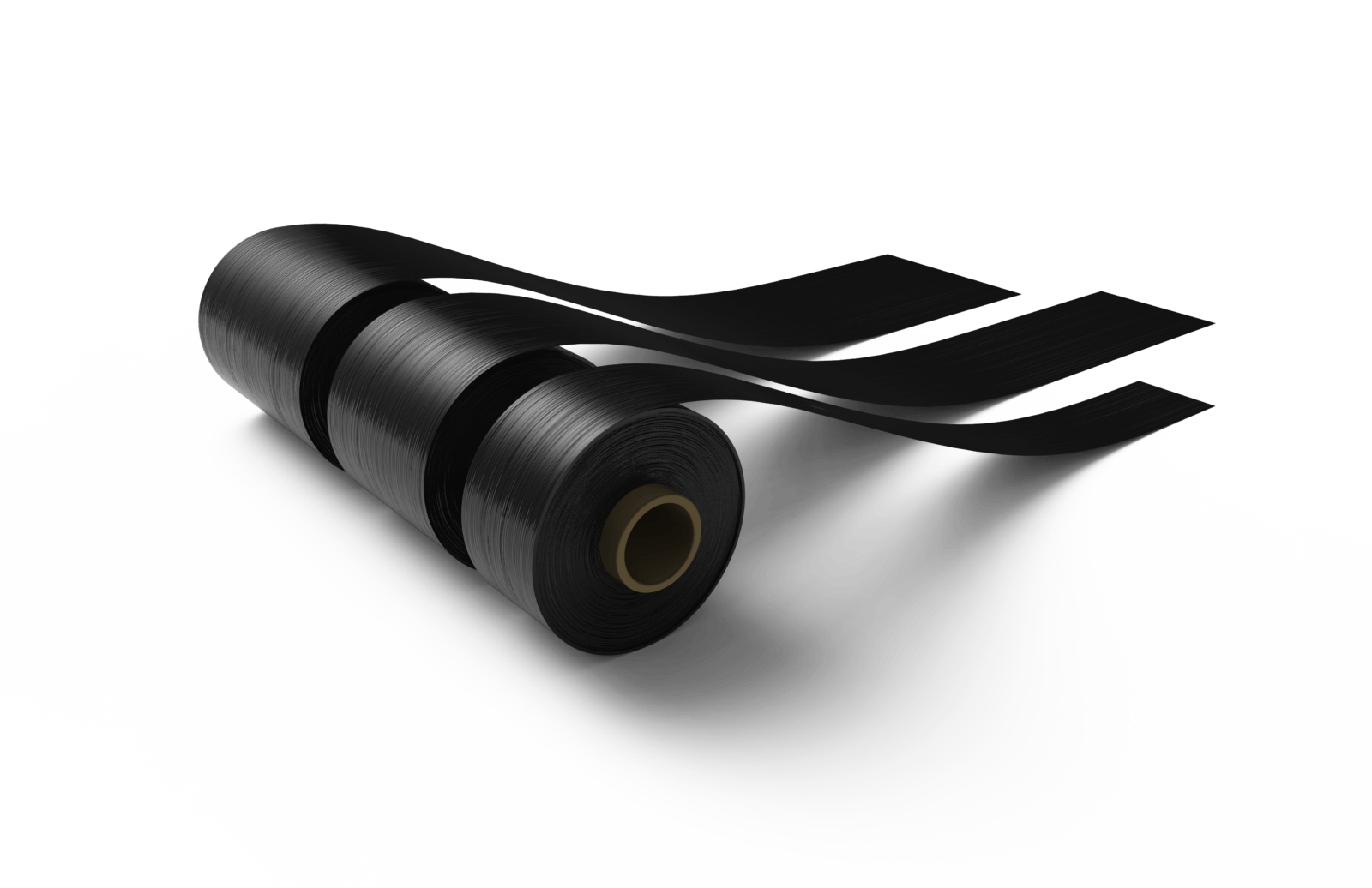

Covestro’s Maezio® thermoplastic carbon fiber composite offers more durability and impact resistance. It combines strong carbon fibers with the flexibility of thermoplastics like polycarbonate (PC). This material is being used successfully across various sectors. Our study on the gravel bike frame is the latest application.

Localizing Carbon Fiber Production in Europe

Until recently, much carbon fiber production was centered in Asia. REIN4CED, based in Belgium, is bringing the process to Europe. Using an automated production process, they handle the material accurately and precisely. This design study can become a reality quickly and efficiently in Europe, where gravel bike riding is popular in destinations like Germany and Norway.

The potential of this material is so much more impactful than providing cyclists with a better product — which, arguably, is impressive enough. From improved, automated manufacturing to greater sustainability and more design opportunities, the use of thermoplastic composites has huge potential for the bicycle industry.

1. Improved manufacturing

Today, if you want to manufacture something out of carbon fiber, Asia is the place. It is also a labor intensive process, largely done by hand. The production of carbon fiber bicycle frames takes several weeks. And on top of the lead time it takes to manufacture these products, brands also have to consider how long it is going to take to ship them to Europe.

With our design study partnership, our gravel bike would be produced right here in Europe using Covestro’s carbon fiber composite and REIN4CED’s highly-automated process. This brings the supply line back to Europe, allowing many of the world’s top bike brands who operate here to take back craftsmanship and have more control over the quality of their finished products while also cutting lead times.

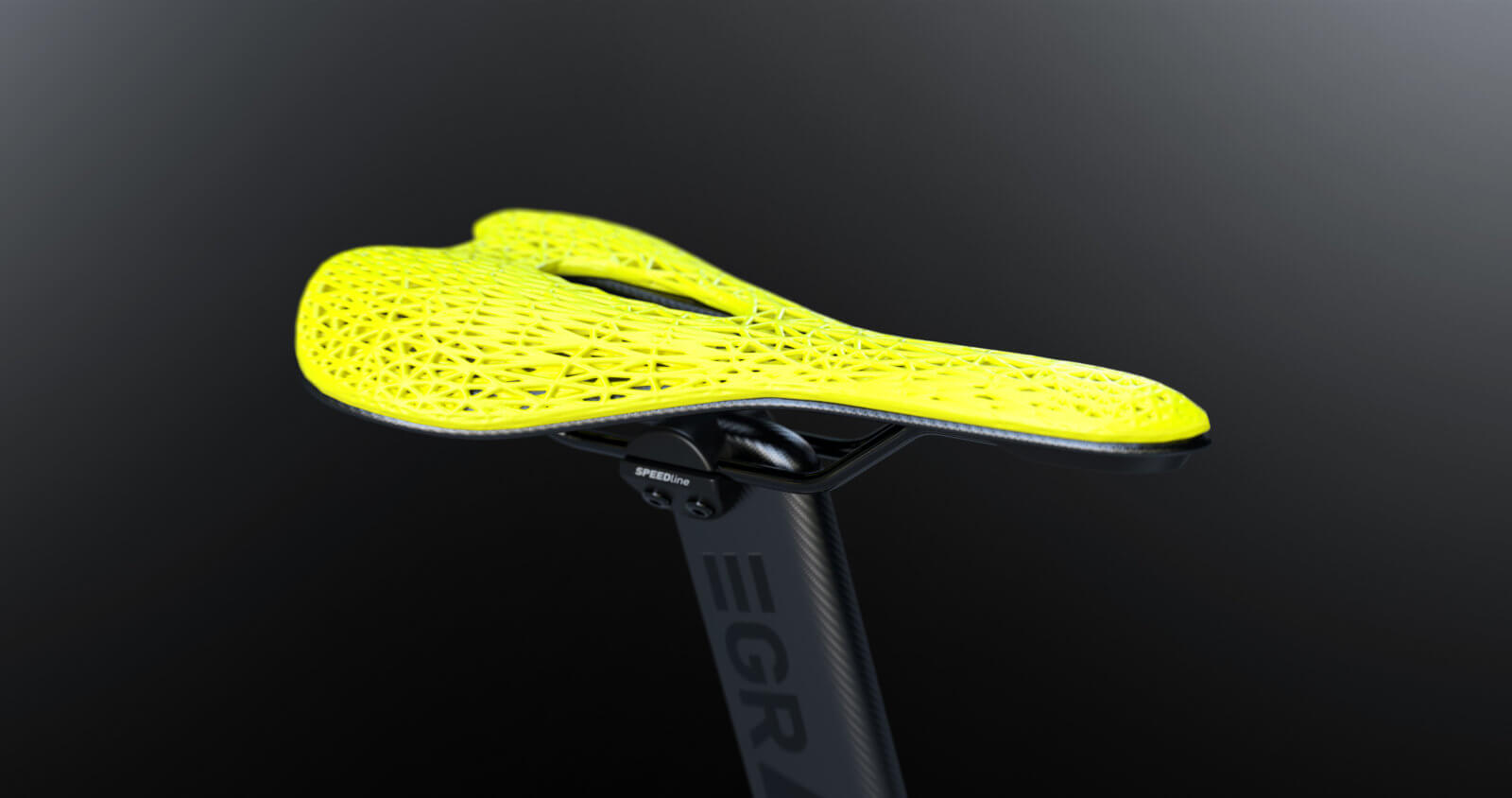

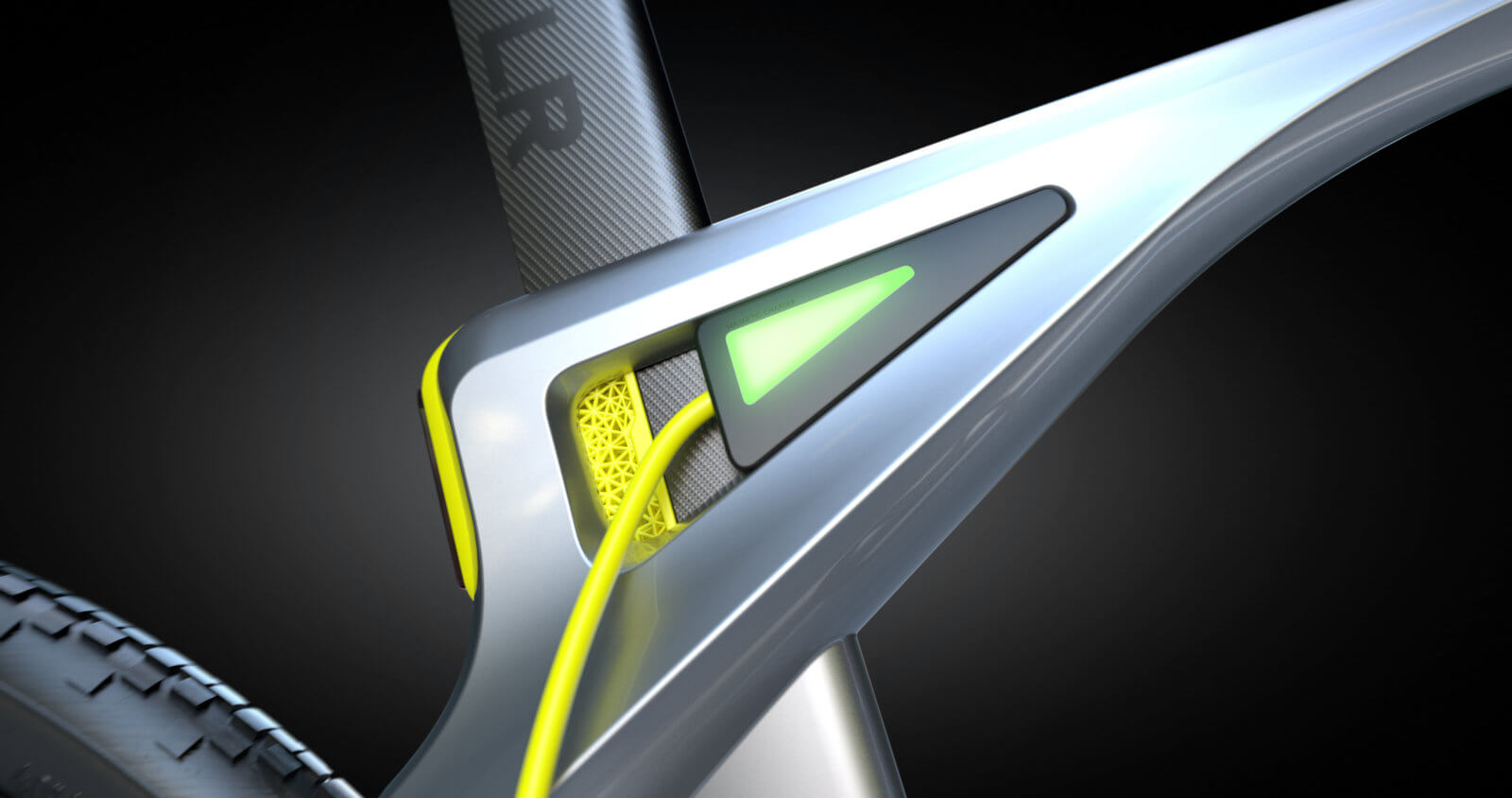

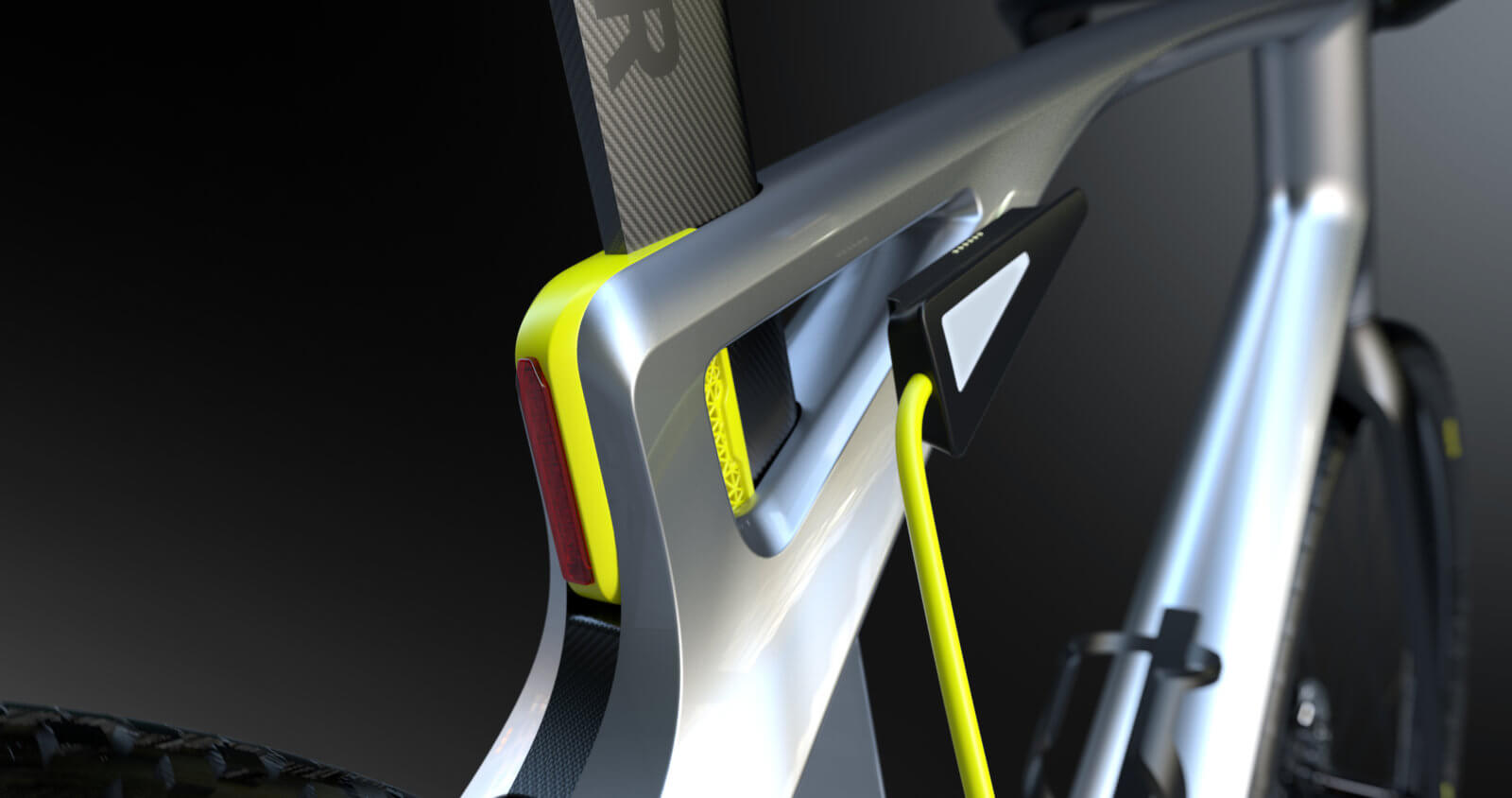

2. More and new design opportunities

As designers, what excites us most are all of the opportunities this new manufacturing process allows us. For example, REIN4CED can use the benefits of thermoplastics which allows us to directly integrate essential parts into the frame — like lights, bike lines, electric wiring and cool new finishes. With aluminum, which is most commonly used in bike frame design, these kinds of integrations and design innovations are not only more difficult to make, but more expensive. With this new manufacturing process we can also create more streamlined designs — getting rid of welding marks and easily integrating key components into the frame.

3. A more sustainable product

At MODYN, our mission is to design products that let people move more freely, easily and sustainably in our world. Unfortunately, aluminum, which is widely used in the bicycle industry, is not sustainable. Mining of aluminum has a huge impact on the environment — from disrupting ecosystems to the pollution that comes from dig sites. You also have to consider all the factors that go into manufacturing, from the excavation equipment to the trains, long-haul trucks, cargo ships, and oil tankers that move the raw

material to processing plants. Plus, there’s the condition of the workers who make the bikes to consider, too. While aluminum is recyclable, a huge amount of energy goes into creating it in the first place.

What’s interesting about working with carbon fiber composites like Covestro’s is that compared to conventional carbon fiber, this composite is based on a thermoplastic, meaning it can be recycled — re-melted and re-formatted — into other products. That is

a huge, important improvement for this material that is already being used efficiently in the auto industry and aerospace. We also think that this material could be instrumental in the micromobility movement — which has its roots in sustainability — by providing an incredibly strong, durable and lightweight bicycle for private and public bike sharing programs. The same goes for bike leasing programs, which will play a huge part in the adoption of the bicycle in metropolitan areas around the world.

4. A transformational trickle-down technology